Why no-code & low-code instruments have turn out to be indispensable in robotics

Utilizing robots is nearly at all times worthwhile for corporations. They’ll cut back labor prices, relieve staff, and make manufacturing extra versatile – as a result of the required batch sizes have gotten smaller and manufacturing processes extra particular person. As well as, a robotic or cobot provides one other main benefit: it will probably work with out breaks and fatigue, thereby growing product high quality and decreasing scrap.

With trendy robotic programs, nearly all processes can now be automated. Normally, robots take over easy, soiled, monotonous, bodily demanding, and even harmful duties. Nevertheless, with the proper {hardware} and, above all, software program, very advanced or notably demanding duties, so-called „Superior Robotics“ purposes, will also be solved. Examples of this embody the meeting of versatile and bendable elements corresponding to cables, wires, or hoses or force-controlled floor processing.

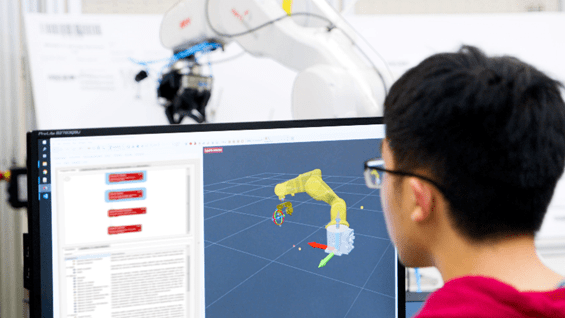

Following the no-code/low-code development, there are numerous software program options available on the market that allow graphical and due to this fact simplified and sooner programming. The benefit is that no particular programming abilities are required. The portfolio ranges from manufacturer-specific options to impartial choices that can be utilized to program robots from completely different producers with one single software program. Particularly within the latter case, specialists advocate utilizing instruments that robotically generate native robotic code for the actual robotic controller as an alternative of controlling the robotic arm by way of a separate IPC.

Within the first case, customers stay versatile with regards to changes or optimizations throughout operation and keep away from a lock-in impact, as they will proceed to program the robotic within the conventional method utilizing line code even with out utilizing the software program.

Whether or not with exterior engineering instruments or line code, there are elements on the trail to robot-based automation that customers usually underestimate and due to this fact don’t pay sufficient consideration to. Find out how to keep away from three of a very powerful obstacles can be briefly defined beneath.

FACTOR 1: PROGRAMMING EFFORT

The time required for programming an software is often not underestimated, however there are different pitfalls on this section: for instance, course of tolerances and variances that haven’t been taken under consideration or the elevated complexity when incorporating sensors or establishing a communication between the robotic and a PLC. As well as, programming a system is commonly a tailored and sophisticated resolution that’s tough to adapt. Furthermore, programmers usually have their very own type, which may make the ensuing code or program obscure and modify for different programmers. At this level, the market helps the consumer with the aforementioned no-code/low-code options. For instance, with pre-defined operate blocks, packages will be constructed and structured in a transparent and comprehensible method for others. Course of tolerances and variances will also be robotically compensated, analyzed, and optimized through the use of the proper software program. If the corresponding interfaces are already built-in, the hassle required to attach sensors or arrange a PLC communication can be immensely diminished.

FACTOR 2: EFFORT DURING COMMISSIONING

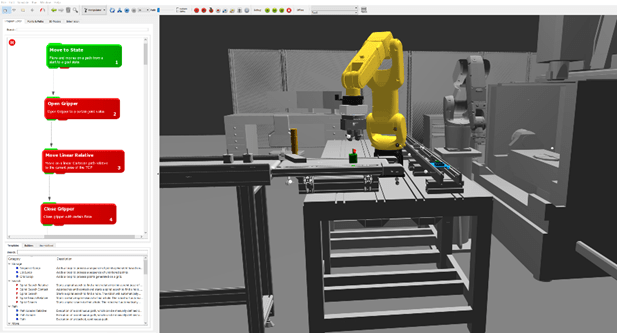

A rule of thumb states that the price of the robotic itself is just about one-third of the preliminary price of the cell, and expertise reveals that round 45 p.c of the standard prices are incurred throughout ramp-up. It is because customers usually underestimate the time required for commissioning. Though the system is programmed offline and simulated all through prematurely, variations between idea and follow usually turn out to be obvious throughout commissioning.

Thus, regardless of good preparation, the method can take considerably longer than deliberate, and changes and modifications can rapidly turn out to be costly As well as, elements that weren’t obvious throughout digital preparation now have to be addressed on-site throughout commissioning. This makes this section tough to calculate. With constant instruments, the ramp-up will be applied in a managed method and with out nice lack of time, in order that this section doesn’t turn out to be a value driver. It is very important mix simulation, programming, sensors, and information evaluation in a single single software program bundle. This fashion, the engineering chain turns into constant with out the consumer having to compromise on performance.

This makes modifications and changes sooner, extra versatile and simpler. With ideally robotically generated robotic code and the power to switch train factors again from the true robotic into the software program, such an answer integrates seamlessly and optimally into present commissioning and upkeep processes. This additionally provides the best flexibility when it comes to on-line and offline programming, permitting the consumer to decide on the best choice and simplest way for the respective job.

FACTOR 3: CHANGES DURING THE LIFECYCLE OF THE CELL

Even when the robotic is working, there may be nonetheless a hazard that’s usually not thought of: Over the system runtime, quite a few modifications typically situations can happen that require adaptation of the programming.

These will be vibrations and shocks, for instance prompted from forklifts or different machines, put on and tear of instruments, substitute components that react in a different way than the earlier elements, modifications in workpiece batches, and the area out there within the corridor or a change of the working personnel. Modified lighting situations and temperature situations or the distinction between a cold-started and warmed-up robotic also can have an effect.

Software program that standardizes and simplifies programming permits the consumer to react merely, rapidly, and flexibly to those and plenty of different modifications and to make obligatory changes in this system itself. If the employee makes use of a instrument that additionally makes modifications or the ensuing penalties seen early on when it comes to forces, cycle instances, or defects and high quality, it turns into simpler to research and derive doable optimizations, which makes the consumer finest ready.

A visitor article by ArtiMinds RoboticsÄhnliche Beiträge