|

Take heed to this text |

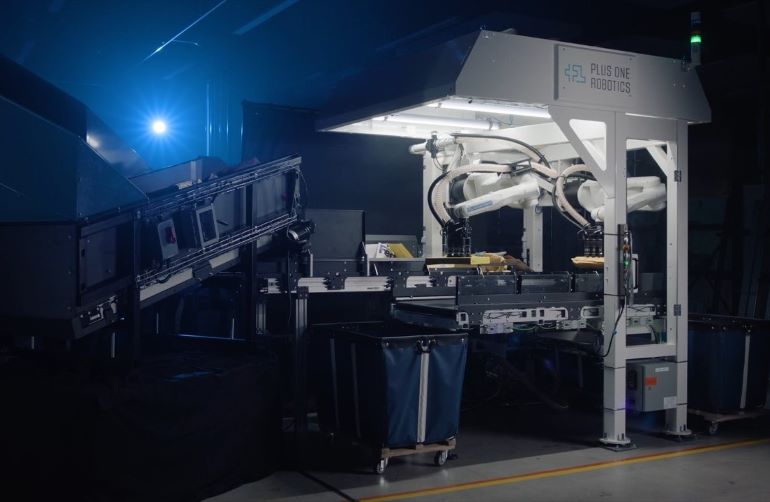

InductOne is designed to deal with a variety of parcels with excessive throughput. Supply: Plus One Robotics

CHICAGO — As gadgets move by warehouses and different services, they’re usually dealt with as packages reasonably than as eaches. Plus One Robotics yesterday launched InductOne, a two-armed robotic designed to optimize parcel singulation and induction in high-volume success and distribution facilities.

“Parcel variability is a major problem of automation throughout the warehouse,” acknowledged Erik Nieves, CEO of Plus One Robotics. “That’s why InductOne is supplied with our progressive particular person cup management [ICC] gripper, which may exactly deal with a variety of parcel dimensions and shapes.”

“But it surely’s not nearly what InductOne picks, it’s additionally about what it doesn’t decide,” he added. “The system avoids choosing non-conveyable gadgets, permitting them to robotically convey to a chosen exception path and stopping the robots from squandering precious cycles dealing with gadgets which shouldn’t be inducted.”

“We’ve doubled down on parcel dealing with; we’re not an every choosing firm,” Nieves informed The Robotic Report. “Imaginative and prescient and greedy for supplies dealing with is difficult, and Plus One continues to give attention to packaged items, which spend most of their time as parcels and could be picked by vacuum grippers.”

InductOne engineered for ease of integration, effectivity

InductOne’s dual-arm design “considerably outperforms single-arm options,” claimed Plus One. “Whereas a single-arm system sometimes tops out at round 1,600 picks per hour, the coordinated movement of InductOne’s two arms can obtain sustained decide charges of two,200 to 2,300 per hour. InductOne’s peak fee maxes out at a fee of three,300 picks per hour, 10% sooner than the main competitors.”

Plus One Robotics mentioned its engineering staff designed InductOne to be succesful however as small as potential for simple integration into brownfield services and to attenuate the necessity for expensive website modifications.

“The engineering strategy behind InductOne has been targeted on effectivity and suppleness,” mentioned Nieves. “We designed the system to be as compact and light-weight as potential, making it simpler to deploy in restricted areas, together with on current mezzanines. The modular and configurable nature of InductOne additionally permits it to seamlessly combine into a wide range of success middle layouts.”

InductOne contains the PickOne imaginative and prescient system, the Yonder distant supervision software program, pick-and-place conveyors, built-in security options, analytics, and coaching and ongoing assist. The modular system can also be provides configurable layouts for cross-belt or tray sorters.

It might probably deal with parcels weighing as much as 15 lb. (6.8 kg) and as much as 27 in. (69 cm) in size, 19 in. (48 cm) in width, and 17 in. (43 cm) in top. InductOne helps bins, clear and opaque polybags, transport envelopes, and padded and paper mailers.

InductOne contains imaginative and prescient and greedy refined by thousands and thousands of picks of expertise. Supply: Plus One Robotics

Plus One Robotics touts expertise and belief

Based in 2016 by pc imaginative and prescient and robotics trade specialists, Plus One Robotics mentioned it combines pc imaginative and prescient, synthetic intelligence, and supervised autonomy to select parcels for main logistics and e-commerce organizations. The San Antonio, Texas-based firm has workplaces in Boulder, Colo., and the Netherlands.

Plus One mentioned it utilized its expertise from greater than 1 billion picks to develop InductOne. The firm mentioned it has realized from dealing with over 1 million picks per day, and reaching the reliability required for such high-volume operations led to its new parcel-handling machine.

“ICC and InductOne are the end result of our learnings from these picks,” mentioned Nieves at Automate. “It’s not simply imaginative and prescient but in addition greedy and conveyance. I push again in opposition to those that say, ‘Knowledge, information, information,” as a result of we additionally want to understand the issues above and under our system. We’re making use of our experience to the issue, however we’re not attempting to be an integrator or only a {hardware} maker.”

Nieves famous that the worth of robotics-as-a-service (RaaS) fashions just isn’t recurring funds however the choice they provide customers to scale deployments up or down as wanted.

“As Pitney Bowes’ Stephanie Cannon mentioned in a panel, it’s essential [for automation providers] to get to 70% confidence after which work with prospects who belief that you just’ll work with them to get the remainder of the way in which,” he mentioned. “{Our relationships} with FedEx and Dwelling Depot for palletization and parcel dealing with are constructed on that belief.”