41.3K

Let’s dive into the fascinating world of FPV drone motors! On this complete information, we’ll discover the ins and outs of motor building, design options, and the components that may affect a motor’s efficiency and effectivity. Having a strong understanding of the design decisions concerned will equip you with the information to select the best motor in your subsequent drone construct.

A few of the hyperlinks on this web page are affiliate hyperlinks. I obtain a fee (at no further value to you) should you make a purchase order after clicking on considered one of these affiliate hyperlinks. This helps help the free content material for the group on this web site. Please learn our Affiliate Hyperlink Coverage for extra data.

Should you’re nonetheless not sure about which motor to decide on, don’t fear! I’ve bought you coated with my prime FPV drone motor suggestions: https://oscarliang.com/top-5-best-motors-mini-quad/

Suggestions

The “finest motor” for an FPV drone relies upon largely in your flying type, requirement, and price range. Personally, I exploit my quads for freestyle, lengthy vary, and infrequently racing and aggressive flying. Due to this fact, I choose versatile motors with balanced efficiency.

Questioning what motor dimension and KV you need to use? Comply with this hyperlink to a desk of suggestions by body dimension, propeller dimension and battery voltage: https://oscarliang.com/table-prop-motor-lipo-weight/.

Motors for 5-inch

When choosing motor KV, 1600-2100KV is for 6S, whereas 2300-2800KV is for 4S. Greater KV choices are typically extra aggressive and power-hungry, whereas decrease KV choices are conservative and environment friendly.

T-Motor Velox Veloce V2207.5 V2

Funds Motor with Respectable High quality

At $14.9 a chunk, the Velox V2207 V2/V3 is maybe the most cost effective value having motors you should purchase right now. It’s a price range providing from T-Motor with fashionable design and options: N52 magnets, titanium shaft and manufactured by the respected T-Motor. They provide completely different KV choices, for cinematic and endurance sorts of flying, I believe 1750KV is nice on 6S. For racing or extra aggressive freestyle flying go for 1950KV-2050KV. For 4S battery, go for 2550KV.

Get the T-Motor Velox from:

RDQ: https://oscarliang.com/product-ahy5

GetFPV: https://oscarliang.com/product-gch4

AliExpress: https://s.click on.aliexpress.com/e/_DDjg899

Amazon: https://amzn.to/3Qp4W1Z

EMAX ECO II 2207

Most cost-effective Value Having

These motors have sturdy N52 magnets and strong construct high quality at a sexy worth level. Whereas you could find motors for much less cash they’re not often value shopping for.

Based on hearsay, Emax is promoting the ECO II motors at a misplaced, simply making an attempt to match the most cost effective motors available on the market. I discovered it to be plausible as a result of this motor is just $16! Now we have no technique to show it, however the Emax ECO II has been confirmed to be among the finest price range FPV motors through the years.

Maybe not one of the best motor for uncooked efficiency, however you may’t actually ask extra as they’re in all probability the most cost effective value having motors presently obtainable. These are nice if you’re simply beginning out or need to construct a basher. It’s additionally an especially environment friendly motor if flight time is vital to you.

They provide 1700KV and 1900KV for 6S, 2400KV for 4S. In addition they do 2306 motor dimension too, however personally I choose the larger stator dimension 2207, it’s extra highly effective and responsive for a similar worth.

Buy the EMAX ECO II 2207 from:

AliExpress: https://s.click on.aliexpress.com/e/_DBfROTx

RDQ: https://oscarliang.com/product-6vdt

GetFPV: https://oscarliang.com/product-8mns

NBD: https://oscarliang.com/product-vc8d

Amazon: https://amzn.to/3wQE9Ey

iFlight Xing2 2207

Tried and True

It has a lot of the desired options in a contemporary FPV drone motor: unibell design, titanium shaft, slotted arc magnets for sooner response, sturdy N52 magnets and a protecting o-ring to maintain the bearings smoother for longer.

Aside from the distinctive and distinctive curved unibody motor bell that makes it tremendous sturdy, the Xing2 2306 and 2207 motors additionally include a lot of nice options. For instance, a single piece titanium alloy motor shaft, strong 9x4x4 bearings, single-strand winding, and the damping ring between bell and bearing that improves sturdiness.

The Xing2 is a strong motor with excessive torque, which interprets into responsiveness and snappiness in flight. For $21 per motor, you’re getting a prime tier efficiency motor which are usually offered across the $30 worth vary, making it extraordinarily good worth. I’ve been flying the Xing2 on my new Supply One V5 construct, and it’s one of many smoothest in my fleet.

The iFlight Xing2 motor line-up affords many alternative KV relying on what LiPo voltages you propose to make use of (4S or 6S), propellers and flying kinds. For 2207, there are 1855KV (6S) and 2755KV (4S), for 2306, there are 1755KV (6S) and 2555KV (4S).

Get the iFlight Xing2 2207 right here:

AliExpress: https://s.click on.aliexpress.com/e/_DefjM73

RDQ: https://oscarliang.com/product-2bz1

GetFPV: https://oscarliang.com/product-hzvo

Banggood: https://oscarliang.com/product-ag8w

Amazon: https://amzn.to/3OJa4v3

Motors for 7-inch

Listed here are my motor suggestions for 7″ FPV drones. Our focus is on effectivity at cruising speeds for longer flight instances and smoothness to reduce vibration and warmth. These components are important since 7″ drones are sometimes used for long-range flying. For 6S setups, 1300KV motors are superb, whereas for 4S, you may need to go for 1500KV or increased.

EMAX ECO II 2807 1300KV

Heavy Motor that Delivers Excellent Efficiency

The EMAX ECO II 2807 motor is a heavyweight contender within the 7-inch quad class. Weighing round 54 grams with 7-inch wires, this motor stands out with its bigger stator dimension. It options multicore windings, a two-piece bell design, and an M2 shaft screw.

Efficiency-wise, the EMAX ECO II 2807 affords a strong mixture of thrust, torque, and effectivity. Its excessive torque ensures a responsive and steady flight expertise, which is essential for capturing clean footage. Whereas the added weight could be a drawback for these conscious of their drone’s whole weight, the EMAX ECO II 2807 excels in delivering energy and stability, making it a strong selection for pilots in search of energy and stability of their 7-inch quad setup.

Get the EMAX ECO II 2807 right here:

AliExpress: https://s.click on.aliexpress.com/e/_DC1zRl3

RDQ: https://oscarliang.com/product-i258

GetFPV: https://oscarliang.com/product-yn40

Amazon: https://amzn.to/3RLyvLL

T-Motor F90 2806.5 1300KV

Light-weight and Environment friendly Motor

The T-Motor F90 2806.5 1300KV is among the best motors for 7-inch drones, providing balanced efficiency. It’s comparatively low in responsiveness, making it extra fitted to long-range builds moderately than freestyle flying.

Should you prioritize effectivity and lengthy flight instances, this motor is value contemplating. For these looking for light-weight motors however with extra responsiveness for freestyle, the Flyfish Flash 2806.5 could be different.

Get the T-Motor F90 right here:

AliExpress: https://s.click on.aliexpress.com/e/_Del6L3f

RDQ: https://oscarliang.com/product-fq2e

GetFPV: https://oscarliang.com/product-t3k7

Amazon: https://amzn.to/47P8Q9y

Motors for 3-inch

Motors for 4-Inch and Ultralight 5-Inch (Sub250) Drones

Beneath 250-gram 4″ and 5″ builds are gaining reputation as a result of latest drone rules. Listed here are some prime decisions on this class.

Emax ECO II 2004

Greatest Worth in its Class

The Emax ECO II 2004 motor is a standout price range choice in its class. It delivers dependable efficiency with out breaking the financial institution, making it a strong selection for cost-conscious builders. Get 3000KV for 4-inch on 4S, 2000KV for 5-inch on 6S.

Get the EMAX ECOII 2004 right here:

AliExpress: https://s.click on.aliexpress.com/e/_DmBpqF1

RDQ: https://oscarliang.com/product-05va

The place to Start?

Should you’re new to the FPV scene, I extremely advocate trying out our newbie’s information to FPV drones first for the fundamentals: https://oscarliang.com/fpv-drone-guide/

Earlier than selecting a motor, it’s vital to have a minimum of a tough concept of the dimensions and weight of the drone you propose on constructing. I’ll stroll you thru the method of figuring out motor dimension primarily based on the drone you are attempting to construct, however should you’re specializing in constructing a 5″ FPV drone, be at liberty to skip forward to the “Motor Measurement” part.

A few of the most important components to bear in mind embrace:

- Motor weight

- Energy (thrust)

- Effectivity (grams per watt)

- Torque and response (RPM adjustments)

Brushless vs. Brushed Motors

On the planet of FPV drones, there are two major motor varieties: brushless and brushed motors. Usually, we are likely to brushless motors as they’re extra sturdy and highly effective, whereas brushed motors are sometimes utilized in low-cost toy drones as they’re less expensive to make. On this information, we’ll be focusing solely on brushless motors, that are the go-to selection for contemporary FPV drones.

Estimating Drone Weight and Body Measurement

When contemplating your FPV drone’s whole weight, make certain to account for all elements: body, FC, ESC, motors, propellers, RX, VTX, antenna, ESCs, LiPo battery, GoPro, and so forth. Whereas it doesn’t must be 100% correct, a detailed estimation is crucial. It’s higher to overestimate the burden and have further energy than to underpower and battle throughout takeoff.

By figuring out your body dimension, you’ll be capable to set up the utmost propeller dimension allowed. For extra data on propeller choice, try our information on how to decide on propellers for FPV drones: https://oscarliang.com/propellers/

Figuring out Thrust Necessities

To calculate the minimal thrust required in your motor and propeller mixture, you’ll want the estimated whole weight of your drone. A basic rule of thumb is that the utmost thrust produced by all motors must be a minimum of double the whole weight of the quadcopter. Inadequate thrust can lead to poor management response and difficulties to elevate off.

For instance, when you have a 1kg drone, the whole thrust generated by the entire motors at 100% throttle must be a minimum of 2kg. That’s 500g thrust produced by every motor for a quadcopter. In fact, having extra thrust obtainable than wanted is at all times a bonus.

For racing drones, the thrust-to-weight ratio (or power-to-weight ratio) must be considerably increased than the instance above. Ratios of 10:1 and even 14:1 usually are not unusual. For acro and freestyle flying, I like to recommend having a minimum of a 5:1 ratio.

The next thrust-to-weight ratio provides a quadcopter better agility and acceleration however could make it tougher to manage, particularly for rookies. Even the slightest throttle contact can “shoot the quad into orbit like a rocket.” Piloting ability and expertise play a major function in managing this energy.

Even should you solely plan to fly a sluggish and steady aerial images rig, purpose for a thrust-to-weight ratio increased than 3:1 and even 4:1. This not solely offers higher management but in addition leaves room for further payload.

Connecting a Brushless Motor

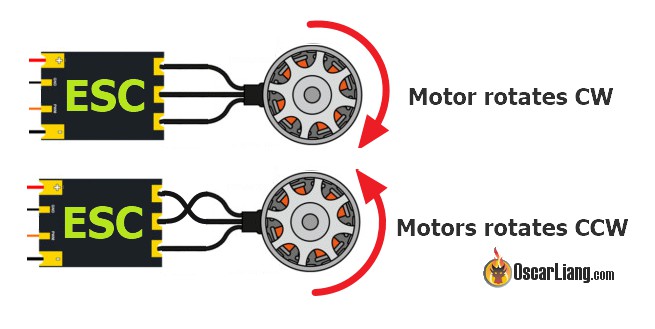

To drive a brushless motor, you’ll want an ESC (digital velocity controller). Not like brushed motors which have solely two wires, brushless motors have three wires. You possibly can join these wires to the ESC in any order. To reverse the rotation path, merely swap two of the three wires. Moreover, it’s potential to reverse motor path via software program settings: https://oscarliang.com/change-motor-spin-direction-quadcopter/

Motor Measurement Defined

Brushless motor dimension in RC is usually indicated by a four-digit quantity – AABB:

- “AA” represents the stator width (or stator diameter)

- “BB” represents the stator top, each measured in millimetres

The stator is the stationary a part of the motor, consisting of “poles” wrapped with copper wires (windings). These poles are made from a number of layers of skinny steel plates laminated collectively, with an ultra-thin insulation layer in between.

Let’s break down the important thing elements of a motor:

- Motor stator: The stationary a part of the motor consists of a number of steel coils. The coil wire is coated in enamel to stop short-circuiting because it’s wound in a number of loops. When {an electrical} present passes via the stator coils, it generates a magnetic discipline that interacts with the everlasting magnets on the rotor, creating rotation.

- Magnets: Everlasting magnets produce a set magnetic discipline. In FPV motors, they’re hooked up to the within of the motor bell utilizing epoxy.

- Motor bell: The motor bell serves because the motor’s protecting casing for the magnets and windings. Usually produced from light-weight metals like aluminium, some motor bells are designed like miniature followers to direct extra airflow over the motor windings for added cooling because the motor spins.

- Motor shaft: Related to the motor bell, the shaft is the working element of the motor that transfers the torque generated by the motor to the propeller.

Growing both the stator width or top will increase the stator quantity, the dimensions of the everlasting magnets, in addition to the electromagnetic stator coils. Because of this, the motor’s total torque is elevated, enabling it to spin a heavier prop sooner and produce extra thrust (on the expense of drawing extra present). Nevertheless, the draw back of a bigger stator is that it’s heavier and fewer responsive.

Evaluating Taller and Wider Stators

Wider motors have bigger inertia when spinning as a result of the mass of the motor is farther from the rotational axis, requiring extra vitality to vary RPM. Consequently, wider and shorter motors are often much less responsive than narrower and taller motors, even when they’ve the identical stator quantity and generate the identical torque. Wider and shorter motors even have smaller magnets on the motor bell, which might cut back the motor’s energy.

Nevertheless, wider motors supply higher cooling because of the bigger floor space on the highest and backside. Temperature is essential to motor efficiency. As a motor heats up, its potential to generate magnetic flux decreases, impacting effectivity and torque manufacturing.

In essence, the width and top of a motor stator signify a stability between responsiveness and cooling. The choice is determined by your flying type. For example, for sluggish cinewhoops carrying a heavy GoPro, you may want motors with wider stator for higher cooling. For quick and responsive racing or freestyle drones, taller stators could be most well-liked.

Wider stators additionally enable for bigger bearings, which might enhance effectivity, smoothness, and longevity.

Greater stators aren’t at all times higher. For instance, 2207 motors can deal with typical 5″ propellers, however utilizing a lot heavier 2506 motors of the identical KV might not present noticeable advantages since they’d produce the identical thrust utilizing the identical propellers, and even present worse responsiveness due to the burden. To enhance efficiency with out including weight, contemplate increased KV motors. The 2506 motor on this instance, nonetheless, would possible work higher for six″ props than 2207 because of the elevated torque necessities.

Motor Torque

Excessive torque motors present fast RPM adjustments and sooner response time, resulting in much less prop wash oscillation and snappier responses.

Motor torque is determined by a number of components, together with:

- Stator dimension (quantity)

- Supplies: the kind of magnets and high quality of copper windings

- Motor building: comparable to air hole, variety of poles, and so on.

Since FPV motors have related specs and designs in recent times, stator dimension is the best technique to quantify torque.

Stator dimension could be calculated utilizing the amount of a cylinder formulation:

quantity = pi * radius^2 * top

For instance, a 2207 motor’s stator quantity is:

pi x (22/2)^2 x 7 = 2660.93

The bigger the stator quantity, the extra torque a motor can generate. Evaluating a 2306 motor with a quantity of 2492.85, a 2207 motor has extra torque.

When selecting a motor, evaluate the motor stator quantity and weight. A lighter motor with the identical quantity is preferable, assuming different components being equal. So, why not decide the most important motor obtainable? The reply lies in weight. Motors with larger stator volumes are heavier, so it actually is determined by the appliance.

For instance, light-weight drones don’t require a lot throttle to remain airborne, leaving extra torque obtainable. Paired with lighter pitch propellers, motors can spin them with much less torque. On this case, motor torque necessities are low, permitting for smaller, lighter motors that preserve total weight down.

The one time a much less highly effective motor (with much less torque) is most well-liked is when smoothness is prioritized over responsiveness. Excessive torque motors can change RPM so rapidly that they might really feel jerky and fewer clean. They’ll additionally create extra voltage spikes and electrical noise within the energy system, probably affecting gyro efficiency and total flight efficiency if noise filtering isn’t optimum, resulting in oscillations.

KV

“KV” signifies the variety of revolutions per minute (rpm) a motor turns when 1V (one volt) is utilized with none load (e.g., propeller) hooked up to the motor. For instance, a 2300KV motor powered by a 3S LiPo battery (12.6V) will spin at roughly 28,980 RPM with out propellers mounted (2300 x 12.6). KV is usually a tough estimation specified by the motor producer.

When a propeller is mounted on the motor, RPM decreases drastically as a result of air resistance. Greater KV motors will attempt to spin the propeller sooner, producing extra thrust and energy (whereas drawing extra present). Bigger props are sometimes paired with low KV motors, whereas smaller, lighter props work higher with excessive KV motors.

Motor KV is decided by the variety of copper wire windings within the stator. Normally, the next variety of winding turns decreases motor KV, whereas a decrease variety of turns will increase it. The magnetic energy of the magnets can even have an effect on the KV worth, with stronger magnets rising KV.

If a excessive KV motor is paired with an excessively giant propeller, the motor will attempt to spin quick as it will with a smaller prop, requiring extra torque. This elevated torque demand will result in increased present draw and warmth technology. Overheating could cause the motor to burn out, because the coil’s coating might soften and trigger electrical shorts contained in the motor. That’s why a increased KV motor is prone to run hotter than a decrease KV motor of the identical dimension.

KV additionally impacts the present and voltage limits of a motor. Greater KV motors have shorter windings and decrease resistance, decreasing the utmost voltage ranking and rising the present draw for the motor and propeller combo. Nevertheless, the motor’s product web page will specify the allowable voltage and most present.

Betaflight’s “Motor Output” restrict lets you cut back the motor sign and use increased voltage batteries (for instance, flying 4S motors on 6S battery). Nevertheless, whereas this workaround may go, it may probably blow your ESC with excessive KV motors. By limiting motor output, you’re setting a restrict on how lengthy the MOSFET stays switched on, however you continue to expose the motor to increased voltage. That is extra prone to trigger points than utilizing a decrease KV motor rated for the upper voltage. It is suggested to decide on the suitable KV motors for the battery voltage you propose to make use of.

Unsure how to decide on motor KV? Test this desk: https://oscarliang.com/table-prop-motor-lipo-weight/

KV vs. Torque Fixed

Motor KV doesn’t immediately have an effect on torque, however it does impression the torque fixed. The torque fixed of a motor defines how a lot present is required to supply a certain quantity of torque. KV doesn’t affect the precise torque generated; components comparable to magnet energy, air-gap, and coil resistance have a way more vital impression on torque manufacturing.

Greater KV motors have the next torque fixed, which means they want extra present to generate the identical quantity of torque in comparison with a decrease KV motor. To generate the identical quantity of torque, the upper KV motor requires extra present, leading to further losses within the ESC, battery, and wires. Furthermore, extra warmth builds up within the motor because of the increased present, much less magnetic flux is generated. General, the next KV motor is much less environment friendly should you had been to fly on the identical velocity because the decrease KV motor.

Due to this fact, it’s a good suggestion to not go overboard on KV; attempt to preserve it average. That is particularly vital when constructing a long-range rig that prioritizes effectivity and flight time.

Motor Mounting

Frequent mounting patterns (gap distance) for 22xx, 23xx, 24xx motors are 16x19mm and 16x16mm. Trendy 5″ FPV drone frames ought to help each patterns. The mounting holes of those motors use M3 screws. Use screws with a thread size 2mm longer than the thickness of the arms; for instance, for 5mm arms, use 7mm screws, and for 6mm arms, use 8mm screws.

Poles and Magnets

When looking motors in your FPV drone, you may come throughout specs comparable to “12N14P” printed on the field. Right here’s what these numbers imply: the quantity previous the letter “N” signifies the variety of electromagnets (poles) within the stator, whereas the quantity earlier than “P” represents the variety of everlasting magnets within the bell.

Totally different motor sizes have various numbers of poles; for example, 22XX and 23XX motors usually function 12 poles and 14 magnets.

The variety of poles has a direct impression on motor efficiency. If there are fewer poles, you may incorporate extra iron content material into the stator, leading to better energy output. Nevertheless, the next variety of poles results in a extra evenly unfold magnetic discipline. This, in flip, offers a smoother-running motor with finer management over the rotation of the bell.

In a nutshell:

- Extra poles = Smoother efficiency

- Fewer poles = Elevated energy

Since FPV drone motors are sometimes 3-phase, the pole configuration should be a a number of of three (i.e., 9, 12, 15, 18, and so on.). That is because of the presence of three wires connecting to the motor. Consequently, the pole quantity isn’t simply modified and isn’t a crucial issue when choosing motors, significantly for FPV drones. However you need to take note of the pole quantity as it’s a must to enter this quantity in Betaflight when enabling RPM filter. Should you can’t discover this quantity, you may merely rely what number of magnets within the bell.

Motor Windings

The variety of copper windings or ‘turns’ on a stator pole determines the utmost present a motor will draw. Concurrently, the thickness of the wire influences the motor’s potential to deal with present earlier than reaching the purpose of overheating.

In easier phrases, fewer turns translate to much less resistance, leading to the next KV. Nevertheless, this additionally results in a diminished electromagnetic discipline on the stator and, consequently, decrease torque.

On the flip aspect, when there are extra turns within the coil, the elevated copper creates a extra substantial magnetic discipline on the stator pole, producing better torque. However there’s a catch – the longer wires and better resistance trigger the motor’s KV to lower.

So, how do producers tackle these challenges when boosting the facility of FPV drone motors? The reply lies in rising the variety of windings whereas using thicker copper wires. This ingenious method successfully reduces the winding resistance, thereby enhancing energy with out sacrificing effectivity and torque. Furthermore, a motor with a bigger wire gauge can deal with excessive present with out burning out.

It’s vital to notice, although, that using thicker wires and extra windings ends in a heavier motor. Moreover, the winding occupies extra bodily house, which requires a bigger stator. That’s why we’re witnessing the emergence of larger and heavier motors out there, which additionally explains their elevated energy.

Multi-Stranded vs. Single Stranded Windings

On the subject of motor windings, there are two major choices: single stranded and multi-stranded. Every has its personal set of benefits and disadvantages, making them appropriate for various functions.

Single stranded windings use thicker wires, which deal with warmth extra successfully, making them superb for demanding flights that pull plenty of amps (e.g. racing, acro, freestyle and so on). Nevertheless, the thicker wires end in bigger gaps between them, limiting what number of could be wrapped across the stator.

However, multi-stranded windings change a single, thicker wire with a number of smaller ones. These thinner wires don’t carry warmth as effectively and are extra liable to bodily breakage.

Regardless of these limitations, multi stranded windings may supply superior efficiency over single stranded windings because of the tighter packing across the stator, with smaller gaps between the wires, leading to a stronger magnetic discipline. This can lead to enhancements in energy and effectivity. Nevertheless, multi-stranded wire usually is more difficult to attain the identical neatness as single-stranded wires, coupled with the truth that there’s extra insulation layers between multi-stranded coils, it ends in extra air gaps between the wires, which could offset the advantages talked about above.

It’s vital to notice that the neatness of the windings performs an important function, each aesthetically and electrically. Messy windings with quite a few wire crossings result in much less environment friendly magnetic fields, because the wires don’t cross the stator perpendicularly. So, when evaluating motor windings, don’t overlook the significance of a tidy and well-organized winding job.

Lastly, multi-stranded wire can overheat extra rapidly than single-stranded wire, which impacts uncooked energy and effectivity of the motor. General, single-stranded winding might be the higher selection in follow.

Bearing

Motor bearings may not be a continuously mentioned matter because of the lack of information on-line, however they play an important function in your FPV drone’s efficiency. Let’s take a more in-depth have a look at the fundamentals of motor bearings.

The scale of a bearing is decided by the distinction between its outer and interior diameters, not the diameters themselves. Wider bearings can accommodate bigger balls (or marbles) inside them. Whereas bigger balls present better sturdiness and crash resistance, smaller balls supply extra stability and smoothness at excessive speeds and RPMs.

Some motors are marketed as that includes “ceramic bearings,” which use ceramic balls as a substitute of metal ones. Whereas these bearings are certainly smoother, they’re additionally extra liable to breaking.

The bearing’s interior diameter additionally dictates the dimensions of the shaft that can be utilized. A 9mm x 4mm bearing affords stability between sturdiness and smoothness.

Fashionable bearings utilized in FPV drone motors embrace Japanese manufacturers comparable to NSK, NMB, and EZO. Though EZO bearings are sometimes hyped as one of the best, it’s difficult to quantify their superiority over different manufacturers. Furthermore, it’s vital to contemplate the opportunity of producers utilizing counterfeit merchandise as a substitute of real ones.

Selecting the Proper Motor Measurement for Your Drone

To find out the best motor dimension in your drone, comply with this sequence: Body Measurement => Prop Measurement => Motor Measurement.

By figuring out the body dimension, you may estimate the suitable motor dimension to make use of. The body dimension constrains the prop dimension, and every prop dimension calls for a special motor RPM to generate thrust effectively—that is the place motor KV comes into play.

Moreover, be sure that the motors produce adequate torque to spin your chosen propeller. This consideration entails the stator dimension. Normally, a bigger stator dimension and better KV end in elevated present draw.

The desk beneath affords a basic guideline. It’s not a inflexible rule, as you might discover folks utilizing barely increased or decrease KV motors than the desk suggests. Nevertheless, it serves as place to begin. This desk assumes you’re powering your quad with 4S LiPo batteries, and the body dimension refers back to the wheelbase (i.e., the diagonal motor-to-motor distance).

For a extra detailed desk encompassing numerous prop sizes and LiPo voltages, verify https://oscarliang.com/table-prop-motor-lipo-weight/

| Body Measurement | Prop Measurement | Motor Measurement | KV |

| 150mm or smaller | 3″ or smaller | 1105 -1306 or smaller | 3000KV and better |

| 180mm | 4″ | 1806, 2204 | 2600KV – 3000KV |

| 210mm | 5″ | 2205-2208, 2305-2306 | 2300KV-2600KV |

| 250mm | 6″ | 2206-2208, 2306 | 2000KV-2300KV |

| 350mm | 7″ | 2506-2508 | 1200KV-1600KV |

| 450mm | 8″, 9″, 10″ or bigger | 26XX and bigger | 1200KV and decrease |

Contemplating Voltage and Present Draw

Understanding the function of voltage in your motor selection is essential. When utilizing the next voltage, your motor will try and spin sooner, resulting in elevated present draw. Be conscious of the thrust your motors generate and the present they demand.

After getting a transparent understanding of the present draw in your motor and propeller mixture, you may confidently choose the suitable ESC in your drone. Remember that the ESC ought to be capable to deal with the utmost present draw of the motor with out exceeding its limits to make sure secure and dependable operation. Learn to select ESC right here: https://oscarliang.com/esc/

How you can Consider Motor Efficiency

After narrowing down your motor dimension, you’ll possible nonetheless have a number of choices to select from. To find out one of the best motor in your particular wants, take the next components into consideration:

- Thrust

- Effectivity and Present Draw

- Weight

In the end, your selection of motor can be influenced by your supposed utility, flying type, and desired efficiency traits.

Thrust

On the subject of selecting a motor in your FPV drone, thrust is commonly the very first thing that involves thoughts. In spite of everything, it’s the power that propels your drone via the air and permits it to carry out these spectacular aerial maneuvers.

Whereas increased thrust interprets into sooner acceleration, it’s essential to not overlook different components comparable to present draw and effectivity. Choosing a motor and propeller mixture that calls for extreme amperage can put undue pressure in your batteries, probably shortening their lifespan.

In case your drone attracts a major quantity of present at excessive throttle, it’s important to make sure that your battery’s most discharge charge is as much as the duty.

Whereas thrust is undoubtedly an important side to contemplate when choosing a motor in your FPV drone, it’s important to weigh it in opposition to different components as talked about beneath.

Motor Weight

Motor weight is an often-overlooked think about FPV drone motor choice, but it performs an important function, particularly for top efficiency drones, comparable to racing drones and freestyle drones.

Motors are mounted on the 4 corners of the body, which suggests they’ve a major impression on the quadcopter’s responsiveness. Heavier motors enhance the angular second of inertia, requiring extra torque (not simply thrust) for the motors to change the drone’s angle.

In real-world flight eventualities, when your quadcopter performs flips and rolls, it takes time to achieve angular acceleration, attain the specified place, after which come to a cease. Heavier motors take longer to succeed in the required angular velocity and decelerate, making the drone really feel much less responsive. That is significantly vital in case your flying type entails fast adjustments in path, comparable to freestyle and racing. For these primarily centered on cruising in a straight line, like cinematic cruisers, motor weight might not be as crucial.

Effectivity and Present Draw

When selecting an FPV drone motor, it’s vital to contemplate motor effectivity, sometimes calculated by dividing thrust by energy at 100% throttle, measured in grams per watt (g/w). The next quantity signifies a extra environment friendly motor.

Nevertheless, don’t simply have a look at effectivity on the prime finish. Analyze effectivity all through your entire throttle vary, particularly across the throttle vary you can be principally fly at. Some motors could also be environment friendly at decrease throttle ranges however lose effectivity as they draw increased present nearing their limits.

One other helpful metric for gauging effectivity is “grams per amp” (thrust/present).

Usually, as thrust will increase, so does the present required to supply it. Due to this fact, motors with excessive thrust and low present draw are preferable. Inefficient motors might generate inadequate thrust or draw extreme present.

Every motor reacts otherwise to numerous propellers. Choosing the proper propeller is essential for balancing thrust and effectivity.

Remember that effectivity and present draw additionally affect battery choice. An environment friendly motor with a excessive present draw might abuse your battery and trigger voltage sags, so it’s important to strike the suitable stability to optimize your drone’s efficiency.

Superior Motors Efficiency Components

Some drone motor traits usually are not explicitly talked about by producers and may solely be found via extra in-depth technical testing. Listed here are just a few superior components to contemplate when choosing a motor:

- Torque

- Response Time

- Temperature

- Vibration and stability

Motor Torque

Torque is the power answerable for turning the propeller, figuring out how rapidly a motor can enhance and reduce its RPM. In different phrases, it gauges how simply a motor can transfer the rotor, propeller, and most significantly, the air.

The torque of a motor considerably impacts your quad’s efficiency, particularly its precision and responsiveness throughout flight. A high-torque motor delivers a snappier response as a result of sooner RPM adjustments. You might even expertise diminished prop wash with elevated torque.

Moreover, excessive torque permits using heavier propellers (although on the expense of upper present draw). If a low-torque motor is tasked with spinning a propeller that’s too heavy for it (also called over-propping), the motor will battle to generate sufficient power to succeed in the specified RPM, leading to poor effectivity and overheating.

Nevertheless, high-torque motors do have one potential downside: oscillation. These motors can change RPM so quickly that they might truly amplify errors (within the flight controller PID loop), resulting in oscillations that may be tough to remove even with PID and filter tuning.

Torque is immediately influenced by the stator dimension, usually with a bigger stator equating to extra torque. Different components that may enhance torque embrace:

- Stronger magnets

- Minimizing the air hole between everlasting magnets and the stator, comparable to utilizing arc magnets

- Thinner stator laminations

One other benefit of high-torque motors is their elevated tolerance for bigger propeller pitch and dimension, permitting them to carry out higher with a wider vary of propellers. Nevertheless, utilizing lighter propellers may also be useful, as RPM adjustments happen extra rapidly.

Response Time

Motor response time is carefully associated to torque, with high-torque motors sometimes having sooner response instances. A simple technique to measure response time is to evaluate how lengthy it takes for a motor to succeed in most RPM from 0.

Response time is closely influenced by the burden and pitch of your chosen propeller. Remember that atmospheric circumstances can even play a job. For example, at decrease altitudes, the air is denser, which means there are extra air molecules that the propeller wants to maneuver as a way to generate thrust. At increased altitudes, your propellers will spin sooner and reply extra rapidly to throttle adjustments, however the total thrust can be diminished as a result of fewer air molecules for the prop to work together with.

Temperature

Temperature performs an important function within the efficiency and longevity of brushless motors. The magnets utilized in these motors exhibit a weaker magnetic discipline at increased temperatures, which might result in sooner demagnetization and have an effect on the motor’s lifespan.

Over-propping your motors or excessively utilizing full throttle could cause your motors to run sizzling. This, in flip, can degrade the motor’s efficiency and the magnets over time. Because of this, motor designs that facilitate cooling usually correlate with longer lifespans.

Vibration

Vibration stemming from motors can result in a number of undesirable penalties in your quad’s efficiency.

A motor with poor stability or subpar construct high quality might generate vibrations that may impression your PID controller. With vibration frequency altering at completely different throttle ranges, tuning your quad can develop into more and more difficult.

Moreover, a motor experiencing vibration will produce extra electrical noise than a easily operating motor. This electrical noise can intrude along with your gyro sensor, additional hampering flight efficiency, and will even degrade your FPV video high quality in case your FPV system is powered immediately from the drone battery.

To mitigate vibration points, most flight controllers include soft-mounted options comparable to rubber grommets, which give vital enhancements. Nevertheless, it’s important to keep in mind that broken, bent, or unbalanced propellers can even contribute to problematic vibrations. Be sure that to examine your propellers commonly and change them as wanted to take care of optimum efficiency.

Key Options of FPV Drone Motors

Motor efficiency could be influenced by many components, making it a fancy and generally controversial matter. Motors with the identical stator dimension and KV can exhibit various thrust, present draw, and response instances, even when utilizing an identical props. Each design and materials decisions can considerably impression efficiency.

On this part, we’ll discover numerous motor design options that contribute to enhanced efficiency and may alter the motor’s traits.

Motor Shaft

The motor shaft is an integral a part of a brushless motor, because it’s answerable for mounting the propeller securely. Most brushless motors designed for 3″, 4″, 5″, and 6″ propellers have M5 shafts with a 5mm diameter.

Motor shaft building has advanced over time to supply higher efficiency and sturdiness:

- Strong Aluminum Shafts: Prior to now, motor shafts had been produced from strong aluminum rods. Whereas they had been light-weight, these shafts had been much less stiff and extra liable to bending.

- Hole Titanium Shafts: To deal with the problems with strong aluminium shafts, producers started utilizing hole titanium shafts. These shafts supplied related weight financial savings however had been considerably stiffer and extra immune to bending. Nevertheless, drilling a gap via the middle of the titanium shaft elevated manufacturing prices.

- Hybrid Shafts: Extra just lately, some motor producers have developed a hybrid shaft design by inserting a metal rod contained in the hole titanium shaft. This revolutionary design combines the stiffness and energy of metal with the light-weight properties of titanium, offering superior efficiency and sturdiness.

Magnet Sort

Magnets utilized in brushless motors are graded based on their magnetic discipline energy, comparable to N50, N52, N54, with increased numbers indicating a stronger magnetic discipline. For instance, a motor with N52SH magnets can be higher than one with N50SH magnets.

A stronger magnetic discipline theoretically permits the motor to generate energy extra effectively, leading to increased torque and sooner response instances. Nevertheless, a motor with a stronger magnetic discipline will sometimes produce extra notches when turned by hand. This isn’t essentially factor, because it signifies a much less even magnetic discipline, which might result in a much less clean motor. You may discover some motors would really feel extra “notchy” than others when spun by hand, that’s a mirrored image of how sturdy the magnets are. Stronger magnets make the motor extra notchy.

It’s additionally vital to notice that magnets can lose their magnetic energy at excessive temperatures, which might impression motor efficiency. To deal with this situation, motor producers usually use N52H magnets, that are designed to resist excessive temperatures. Some motors even use N52SH magnets, that are believed to have the ability to stand up to even increased temperatures.

Lastly, it’s not unusual for magnets to develop into unfastened in crashes or as a result of vibration. To repair this situation, you should utilize Loctite 438 to connect the magnets again in place throughout the motor bell.

Curved Magnets

Utilizing magnets, also called arc magnets, is a way that permits magnets to be introduced nearer to the stator, permitting for a smaller and extra constant air hole. This, in flip, offers higher efficiency in motors.

With curved magnets, the strongest magnetic level of every pole is now not on the floor of the magnet, not like customary non-curved magnets. The epicentre of the sector of the pole on the surface of the curve can be beneath the floor of the magnet, and the epicentre of the pole on the interior curve will truly be above the floor, bringing the magnetic fields of the everlasting and electromagnets even nearer collectively.

Along with the form of the magnets, some producers take a look at mini quad motors with completely different thicknesses of magnets, and have discovered {that a} barely thinner magnet (and subsequently a weaker magnetic discipline) can even make a noticable distinction in efficiency.

Air Hole

“Air hole” in a motor refers back to the distance between the everlasting magnets and the stator. Magnetic power degrades non-linearly with distance, so decreasing the hole between the 2 considerably boosts the facility of the motor. A smaller air hole not solely makes the motor extra highly effective, it additionally improves torque and response.

The draw back of tighter airgap is the rise in present draw and reduce in effectivity. Additionally there’s concern relating to sturdiness, if the motor bell takes any form of impression and it will get out of alignment and shifted in any respect, the magnet can run into the stator and find yourself getting shattered.

Stator Laminations

A lamination is the thickness of the person sheets of steel stacked up within the motor stator. Thinner lamination permits for extra layers of stator plates to be stacked for a similar top of the motor stator.

Normally, thinner stator laminations are higher for motor efficiency. They assist to scale back a phenomenon referred to as Eddy Present, which generates warmth in a altering magnetic surroundings. Thinner laminations imply much less energy is wasted on producing eddy currents, leading to extra environment friendly and highly effective motors.

C-Clip / Shaft Screw

On the subject of securing the motor shaft, FPV drone motors use considered one of three strategies: C-clips, E-clips, or screws. Every technique has its personal set of benefits and downsides, making it tough to find out which one is one of the best.

Usually talking, screws are simpler to take away and are higher for consumer upkeep than C-clips or E-clips. Nevertheless, screws have the next threat of being over-tightened, which might lock the shaft and make the motor more durable to spin.

However, there have been reviews of C-clips popping off throughout flight, which might trigger the motor bell to fly off and result in a crash. Whereas screws might appear to be a safer choice, they aren’t proof against this downside.

Aluminium Alloy

The steel used for the motor bell and motor base determines the sturdiness of the motor. There are two frequent sorts of aluminium alloy utilized in FPV motors: 7075 and 6082. The quantity designates the completely different collection of aluminium alloy grades and chemical composition.

In a nutshell, 6082 has extra ductility and is extra formable whereas 7075 is extra inflexible and maintain up higher in opposition to crashes. 6082 is used again within the days earlier than 2016/2017, however 7075 is the commonest in fashionable motors and is regarded as stronger in opposition to impression.

Unibell

There are two sorts of bell designs: 2-piece bell design, and Unibell design.

The two-piece bell design entails a machined prime aluminum half coupled with a metal flux ring bonded beneath it, a standard and extensively used building in motors.

The Unibell design options an aluminum bell extending down over a metal flux ring – like a skinny protecting sheath surrounding the metal flux ring.

The one-piece building of the Unibell design provides a slight weight achieve to the motor over two-piece bell design, nonetheless it improves sturdiness and reduces the danger of the motor bell slipping down—a standard situation in some two-piece bell designs. Motors with a two-piece design can undergo from a separation of the flux ring from the highest a part of the bell throughout a tough crash, rendering the motor ineffective. Nevertheless, that is just about exceptional with the Unibell design because of the in depth adhesive space, which ensures a agency and safe bond between the 2 elements.

Regardless of the small weight penalty, the added sturdiness supplied by the Unibell design justifies the fee in my view. In spite of everything. A negligible enhance in weight results in a considerable achieve in resilience, a trade-off that’s value making.

Flux Ring Design

A flux ring is the spherical metal ring contained in the bell that comprises the magnets. The bell is often made from aluminium, whereas the flux ring is made from metal as a result of it has to answer magnetic discipline strains.

The most recent flux ring design is a customized form as a substitute of the same old spherical form, which may help direct extra magnetic discipline strains again into the motor and enhance the torque.

O-Ring

O-ring below inside the motor bell is a good function to have in a motor.

The o-ring acts as a buffer/cushion, absorbing among the shock from bodily impacts. This may help preserve the smoothness of the bearing over an extended interval, probably rising the lifespan of the motor. The added safety the o-ring offers can even cut back upkeep wants and the frequency of half replacements, providing each financial and sensible advantages to the customers.

Backside Design

In motor base design, there’s the extra conventional “closed backside” method, and the newer “bare backside” type. There are execs and cons to each of those designs.

The “closed backside” design means a stronger base, nonetheless the “bare backside” are typically lighter by eradicating the surplus materials, the burden saving is round 2g.

Closed base motors are much less prone to get grime trapped contained in the bell, in opposition to the argument that, bare backside are simpler to wash the grime out.

With bare backside, you may see clearly how far the screws are stepping into, and you’ve got much less likelihood of shorting the motor winding if the screws are too lengthy. (This occurs usually to rookies with closed backside motors.)

Bare backside motors are straightforward to get grime contained in the motor, however it’s additionally simpler to wash

Nevertheless, the closed backside offers higher pressure reduction to the wires in case of crashing and stretching.

Silver Plated Copper Wires

Each silver and copper are famend for his or her distinctive conductivity. However silver, being a bigger atom with extra inner electron shells, holds onto its outermost electron very loosely. This implies it may extra readily dissociate its electrons, permitting them to maneuver extra freely via the steel to hold warmth and electrical energy. Thus, silver is a good higher conductor than copper.

By plating silver onto the surface of copper wire, you improve its electrical and thermal conductivity, that are each useful for motors.

Nevertheless silver plated copper wires are far more costly than regular copper wires, subsequently it’s not quite common in price range motors.

PoPo Expertise

The “Pop on Pop off” system is mainly a motor shaft with spring loaded bearing for putting in and eradicating props rapidly. For a extra element overview and product record try this text.

Different Options

- Soldering tabs

- ESC integration

- Cooling design

Motor producers are continuously experimenting with completely different designs and ranges of {hardware} integration, which has led to advances in cooling and even integrating ESC contained in the motor. Personally I believe solder tabs on the motor can come in useful, it lets you use a lighter gauge wire to save lots of weight on much less amp hungry functions. They need to even be simply repairable if the wires get pulled off, which might usually spell the top of a motor of typical design.

CW and CCW Drone Motors

You’ll not often see brushless motors labelled as CW (clockwise) and CCW (counter clockwise).

This doesn’t point out the path the motor spins. Brushless motors can spin both path. This label differentiates the path that the motor bolt is threaded. That is completed in order that because the motor spins, the torque from the propeller pushes the motor nut to tighten moderately than loosen. This retains your props from loosening and coming off when you fly. This implies you will have two of every in your 4 motor format in customary Betaflight rotation.

- Entrance Left: CW

- Entrance Proper: CCW

- Again Left: CCW

- Again Proper: CW

To inform when you have the proper threaded motor on, merely maintain the prop nut on the shaft, then begin turning the motor along with your hand within the path it ought to spin. If the nut tightens then you’ve gotten the proper one 🙂

Personally I choose to have the identical threads on all my motors, so I don’t confuse myself with the completely different prop nuts. If it’s a must to change a prop nut on the ironmongery store, it may be an actual headache looking for a CCW threaded nuts (or extra generally within the {hardware} jargon, a ‘left hand thread nut’). Prop nuts nowadays are lock nuts (have rubber inside), they keep on comparatively effectively when tightened down and doesn’t get unfastened simply.

Edit Historical past

- 2013 – Article created

- 2016 – Added motor suggestions

- 2017 – Added “Motor Options”

- 2018 – Added information about windings, poles, bearing, Torque, mounting sample, PoPo know-how

- 2019 – Added information about ESC connection

- 2022 – Added information about Unibell

- 2023 – Article revised, up to date product hyperlinks

- Could 2024 – Up to date product hyperlinks.