Information briefs for the week check out the evolution of AMR design from Fraunhofer, cargo hold-cleaning robots for bulk-carrying ships, “Roboforming” precision shapes in sheet steel with out chopping dies, ruggedized catastrophe robots, and net-cleaning aquatic robots on fish farms.

Evolving AMR design with ‘evoBot’

Logistics lately has grow to be a hotbed for brand new robotics fashions and expertise, with one new product, the evoBot from the Fraunhofer Institute for Materials Stream, presenting a revolutionary new look.

Formally often known as a “self-balancing autonomous items and packages transporter”, the evoBOT’s two arms, which swing up from their place between the self-balancing legs, can raise 220 lbs., journey at speeds as much as 30 mph, and final for eight hours between recharging.

Formally often known as a “self-balancing autonomous items and packages transporter”, the evoBOT’s two arms, which swing up from their place between the self-balancing legs, can raise 220 lbs., journey at speeds as much as 30 mph, and final for eight hours between recharging.

In distinction to standard robots and AMRs, the evoBOT retains itself completely balanced utilizing the precept of an inverse compound pendulum with out exterior counterweight, which makes the evoBot light-weight and space-saving (see video)

The autonomous transporter sees items and objects by its pair of eyes positioned at its middle bar, whereas embedded mapping sensors add to the robotic’s detection and navigation capabilities.

“EvoBOT can stretch its two arms to lock in objects to hold, flex its arms downward to the ground to behave as a platform and bend right into a V-shape to safe a package deal or field between its legs.

Ship’s cargo holds cleaned by robotic

The cargo maintain of a bulk-carrying ship must be cleaned after it’s emptied, which suggests appreciable manpower, the hazard of falls from heights, publicity to chemical compounds, and different assorted cleansing hazards for the personnel.

Denmark-based CLIIN Robotics has developed a cleansing robotic particularly designed for cargo holds. The corporate’s Cargo Maintain Robotic (CHR), outfitted with high-pressure cleansing instruments and magnetic tracks for climbing the partitions of the cargo maintain, simply replaces a traditional 4-step cleansing course of involving tons of chemical compounds and sea-water flushing. The CHR’s one-step freshwater cleansing course of, claims CLIIN, cuts time spent on cargo-hold cleansing by 50%.

Denmark-based CLIIN Robotics has developed a cleansing robotic particularly designed for cargo holds. The corporate’s Cargo Maintain Robotic (CHR), outfitted with high-pressure cleansing instruments and magnetic tracks for climbing the partitions of the cargo maintain, simply replaces a traditional 4-step cleansing course of involving tons of chemical compounds and sea-water flushing. The CHR’s one-step freshwater cleansing course of, claims CLIIN, cuts time spent on cargo-hold cleansing by 50%.

Utilizing magnets, the robotic crawlers from CLIIN can attain excessive, typically inaccessible areas on metal surfaces of a ship’s cargo maintain, and, if wanted, also can clear the exteriors of a ship’s hull, plus inside/exteriors of oil storage tanks, and wind generators (see video).

Along with easing any antagonistic environmental influence from conventional cleansing procedures, the CHR gives more practical cleansing, as evidenced in March of 2023, with the receipt of two bronze awards—one within the class Security Know-how and one for Rising Know-how—on the World Tank Storage Awards.

CHR makes it attainable for a single crew member to oversee and management the complete cleansing course of, and not using a chemical swimsuit or cleansing equipment.

“Roboforming” sheet steel with out dies

Slicing or stamping out steel elements often necessitates using a producing die for the stamping or chopping course of.  Eliminating the expense of designing and manufacturing such dies is the aim behind Chatsworth, CA-based Machina Labs’ new robotic machining platform.

Eliminating the expense of designing and manufacturing such dies is the aim behind Chatsworth, CA-based Machina Labs’ new robotic machining platform.

Machina Labs’ claims its new robotic manufacturing platform is the primary and solely commercially out there robotic sheet-forming expertise. By combining the newest advances in robotics and AI, the manufacturing platform “quickly kinds and finishes giant, advanced, curved sheet steel elements with none customized tooling.”

Referred to as Roboforming, Machina’s robotic/AI platform positions a FANUC robotic on both facet of a steel plate and makes use of its robotic arms to exactly form the steel with out chopping.

“Machina Labs’ robots use an intensive array of AI-driven sensors to collect information and incrementally manipulate sheet steel to kind giant, advanced elements.” The corporate gathers information for each half to create a digital twin with all of the related course of data. This gives essentially the most correct course of and half qualification data for each single unit made.

Ruggedized robots as catastrophe assistants

Pure disasters appear to be occurring extra often and with ever-greater harmful energy. As frequency and hazard ranges rise, ruggedized technique of first responder safety gear could be of important assist, and a few robotics builders are rising to the problem.

Cumbria, UK-based Forth Engineering says of itself that it makes use of “revolutionary expertise to develop new strategies which permit operators to attain what was beforehand thought-about not attainable.” For Forth, such expertise contains its new, specialised catastrophe automobile, the Rescue Robotic, a remotely operated robotic able to withstanding hazardous nuclear environments. It was efficiently trialed in April (2023) on the Sellafield nuclear web site in Cumbria, UK.

Cumbria, UK-based Forth Engineering says of itself that it makes use of “revolutionary expertise to develop new strategies which permit operators to attain what was beforehand thought-about not attainable.” For Forth, such expertise contains its new, specialised catastrophe automobile, the Rescue Robotic, a remotely operated robotic able to withstanding hazardous nuclear environments. It was efficiently trialed in April (2023) on the Sellafield nuclear web site in Cumbria, UK.

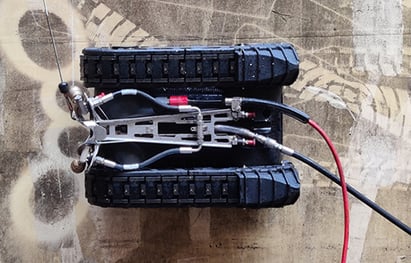

Constructed on a J C Bamford (JCB) tracked compactor/excavator platform, the Rescue Robotic is tetherless and might be managed from as much as 150m away. Forth claims that “strong robotics programs, wi-fi expertise, cameras, and lights can all stand up to hazardous situations.

“By working with Sellafield Ltd,” says Forth’s managing director Mark Telford, “we had been in a position to show the machine is ready to stand up to some notably harmful situations, and its varied variations and capabilities imply that this will likely be an actual asset to the UK’s nuclear trade.”

Internet-cleaning aquatic robotic for fish farms

It doesn’t take a lot to make an enormous bang in robotics. Invention, innovation, and a small funding can do wonders. Norway-based Remora Robotics, with a small $2.7 million helps to remake fish-farm upkeep.

The worldwide fish farming market, at $268 billion, and rising quick (forecast at $490 billion by 2030), most frequently makes use of nets to surround fish shares. The nets, over time, get enmeshed with tons of seaweed and should be cleaned.

The worldwide fish farming market, at $268 billion, and rising quick (forecast at $490 billion by 2030), most frequently makes use of nets to surround fish shares. The nets, over time, get enmeshed with tons of seaweed and should be cleaned.

“The Remora robotic,” reads the web site, “prevents biofouling, improves fish welfare whereas amassing information in regards to the pen’s aquatic setting in a mild and sustainable, energy-efficient and environmentally pleasant means.”

Remora is the primary totally autonomous internet cleaner and inspector. With built-in sensors to watch and examine environmental information, the robotic cleans and inspects fish farming pens whereas amassing information concerning the pen’s aquatic setting.

Remora’s expertise was developed in collaboration with SINTEF, the Norwegian Analysis Council, NTNU and Innovation Norway, examined, accepted, and documented successfully by Norce, Norwegian Analysis Centre.

![]()