A brand new method for 3D printing medicine has enabled the printing of a number of medicine in a single pill, paving the way in which for customized tablets that may ship timed doses.

Researchers from the College of Nottingham’s, Centre for Additive Manufacturing have led analysis alongside the College of Pharmacy that has fabricated customized medication utilizing Multi-Materials InkJet 3D Printing (MM-IJ3DP). The analysis has been revealed in Supplies As we speak Advances.

The workforce have developed a cutting-edge technique that permits the fabrication of personalized pharmaceutical tablets with tailor-made drug launch profiles, guaranteeing extra exact and efficient remedy choices for sufferers.

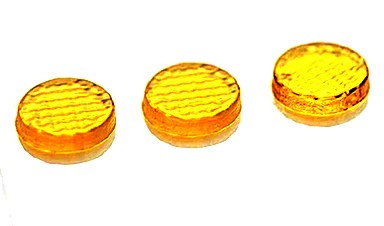

Utilizing Multi-Materials InkJet 3D Printing (MM-IJ3DP), tablets will be printed that launch medicine at a managed charge, decided by the pill‘s design. That is made attainable by a novel ink formulation based mostly on molecules which can be delicate to ultraviolet gentle. When printed, these molecules type a water-soluble construction.

The drug launch charge is managed by the distinctive inside construction of the pill, permitting for timing the dosage launch. This technique can print a number of medicine in a single pill, permitting for complicated medicine regimens to be simplified right into a single dose.

Dr. Yinfeng He, Assistant Professor within the College of Engineering’s Centre for Additive Manufacturing led the analysis, he mentioned, “That is an thrilling step forwards within the improvement of customized medicine. This breakthrough not solely highlights the potential of 3D printing in revolutionizing drug supply but additionally opens up new avenues for the event of next-generation customized medicines.”

“Whereas promising, the know-how faces challenges, together with the necessity for extra formulations that help a wider vary of supplies. The continuing analysis goals to refine these elements, enhancing the feasibility of MM-IJ3DP for widespread utility,” Professor Ricky Wildman added.

This know-how will probably be notably useful in creating medicine that should launch medicine at particular occasions, making it very best for treating ailments, the place timing and dosage accuracy are essential. The power to print 56 tablets in a single batch demonstrates the scalability of this know-how, offering a powerful potential for the manufacturing of customized medicines.

Professor Felicity Rose on the College of Nottingham’s College of Pharmacy was one of many co-authors on the analysis, she says, “The way forward for prescribed medicine lies in a customized method, and we all know that up 50% of individuals within the UK alone don’t take their medicines accurately and this has an influence on poorer well being outcomes with situations not being managed or correctly handled. A single tablet method would simplify taking a number of drugs at completely different occasions and this analysis is an thrilling step in the direction of that.”

Extra data: Geoffrey Rivers et al, Enabling high-fidelity personalised pharmaceutical tablets by way of multimaterial inkjet 3D printing with a water-soluble excipient, Supplies As we speak Advances (2024). DOI: 10.1016/j.mtadv.2024.100493

Supplied by College of Nottingham