CNBC’s Katie Tarasov (left) with Godfrey D’Souza, Apple’s senior director {hardware} validation in a chip lab (Supply; CNBC)

For the primary time, Apple has allowed cameras into considered one of its processor labs the place it assessments designs just like the M3, whereas executives clarify the agency’s method to constructing its personal chips.

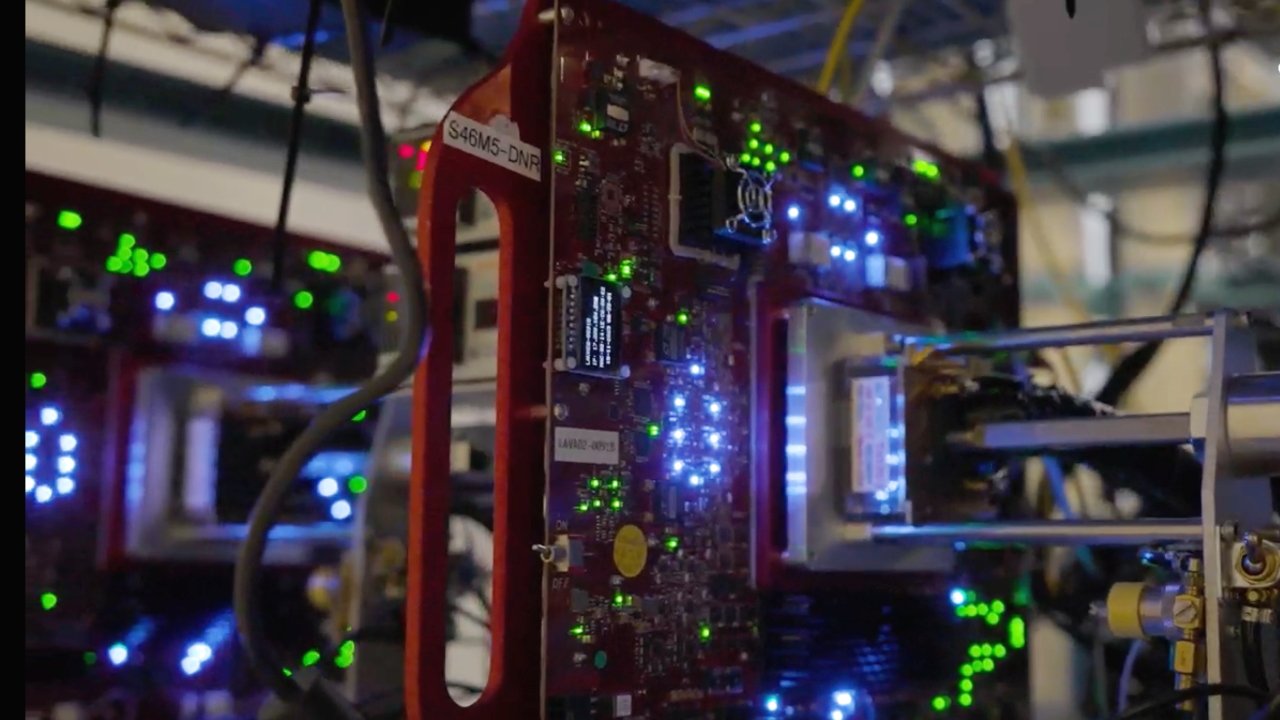

One among Apple’s many processor labs internationally is in Apple Park, the place head of Apple Silicon, Johny Srouji, is predicated. CNBC was proven what journalist Katie Tarasov described as a “easy room stuffed with a pair hundred machines, blinking lights, a handful of engineers and lab coats, and a bunch of postage stamp-sized chips being put by means of rigorous testing.”

“I got here to Apple [in 2008] with the aim of constructing our personal silicon for the iPhone,” Johny Srouji instructed CNBC. “It was a really small staff on the time, about 40 to 50 engineers, and since then we’ve got grown the staff immensely.|

“Now we have 1000’s of engineers 1701531700,” he continued. “However if you happen to have a look at the portfolio of chips we do: very lean, really. Very environment friendly.”

“As a result of we’re not likely promoting chips outdoors, we deal with the product,” he stated. “That offers us freedom to optimize, and the scalable structure lets us reuse items between totally different merchandise.”

One month after Srouji joined, Apple purchased chip firm PA Semi for $278 million.

Then two years later, Apple launched the A4, its first customized chip for the iPhone 4, and the unique iPad. In line with Srouji, although, the plan was at all times to take its processor designs to extra merchandise.

“We constructed what we name the unified reminiscence structure that’s scalable throughout merchandise,” stated Srouji. “We constructed an structure that you simply begin with the iPhone, however then we scaled it to the iPad after which to the watch and ultimately to the Mac.”

“We get to design the chips forward of time,” continued Srouji. He says that his employees and people on {hardware} engineering lead John Ternus, work “to precisely and exactly construct chips which might be going to be focused for these merchandise, and just for these merchandise.”

“Our aspiration is the product,” he stated. “We need to construct the very best merchandise on the planet.”

“As a know-how staff, which additionally contains the chips on this case,” continued Srouji, “we need to construct the very best know-how that might allow that imaginative and prescient.”

For the iPhone 15 Professional, Apple introduced the A17, and iPhone advertising and marketing lead Kaiann Drance says that was “really the largest redesign in GPU structure and Apple Silicon historical past.”

Talking of the transfer to Apple Silicon, Ternus instructed CNBC that “it was nearly just like the legal guidelines of physics had modified.”

“Impulsively we may construct a MacBook Air that is extremely skinny and light-weight, has no fan, 18 hours of battery life,” he stated, “and outperformed the MacBook Professional that we had simply been transport.”

“[The new M3 Max MacBook Pro” is 11 times faster than the fastest Intel MacBook Pro we were making,” he continued. “And we were shipping that just two years ago.”

The future of processor design

Apple has been reported to be working on its own 5G modem to replace the one it licences from Qualcomm, and at times it has been reported to be having difficulties with it.

Unsurprisingly, Srouji would not comment on Apple’s plans for 5G, or any “future technologies and products.” However, he said that “we care about cellular, and we have teams enabling that.”

In the meantime, despite its own processor labs, Srouji says Apple will “buy off the shelf,” if that means its engineers can concentrate “on what really, really matters.”

Designing processors for Apple products is one thing, but of course those designs then have to be manufactured. That has long meant working with TSMC, but most recently Apple has announced a partnership with Amkor to take processors and perform chip packaging before they can be added to devices.