It goes with out saying that it’s very necessary for airliners’ jet engines to be repeatedly inspected. Such inspections may quickly be simpler and extra thorough than ever earlier than, due to a robotic that strikes like an inchworm.

Presently, inaccessible components of jet engines are imaged through borescopes, that are basically lengthy versatile tubes with a video digital camera on one finish and an eyepiece or display screen on the opposite.

The power of gravity usually causes the camera-end of such units to droop down except braced towards an engine half, nevertheless, plus it may be troublesome to maneuver the digital camera deep into the engine. That is the place Sensiworm is designed to return in.

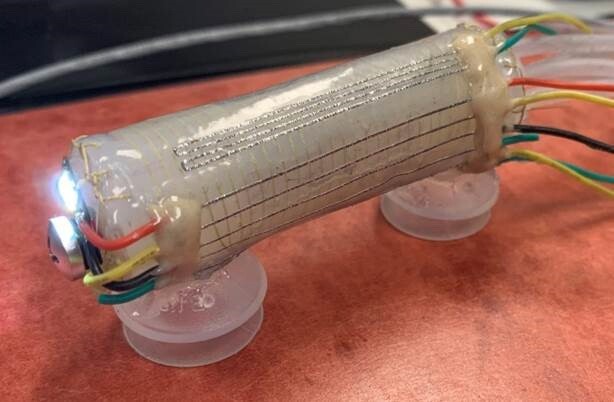

Its identify an acronym for “Gentle ElectroNics Pores and skin-Innervated Robotic Worm,” the bio-inspired soft-robotic system is being developed by a group of GE Aerospace Analysis engineers working with colleagues from New York’s Binghamton College and Ohio-based analysis and improvement group, UES, Inc.

Normal Electrical

After being deployed into the turbine inlet or exhaust port of a airplane’s engine, the compact robotic is ready to make its method by means of that engine through an inchworm-like push-pull type of locomotion facilitated by vacuum cups on its underside. Because the bot does so it transmits dwell video from a forward-facing spotlight-assisted digital camera, imaging any cracks, corrosion or different issues it could encounter.

Importantly, although, Sensiworm would not simply present video. Sensors on the prevailing prototype are able to sniffing out fuel leaks and measuring the thickness of thermal barrier coatings on engine components, with different sensing capabilities at the moment within the works.

Down the street, it’s hoped that the robotic may even be used to carry out remote-control repairs. The ultimate model of the system ought to be fully self-contained and untethered, housing its personal energy provide, microprocessor and different electronics.

“With mini-robot companions like Sensiworm, service operators would have a number of extra units of eyes and ears to carry out on-wing inspections,” mentioned Deepak Trivedi, Principal Robotics Engineer at GE Aerospace Analysis. “With their mushy, compliant design, they might examine each inch of a jet engine transmitting dwell video and real-time knowledge in regards to the situation of components that operators usually examine.”

The robotic’s performance is demonstrated within the following video.

GE Aerospace’s “Sensiworm”

Supply: Normal Electrical