A cutting-edge X-ray methodology reveals the 3D orientation of nanoscale materials constructions, providing contemporary insights into their performance.

Researchers on the Swiss Mild Supply (SLS) have developed a groundbreaking method referred to as X-ray linear dichroic orientation tomography (XL-DOT). This methodology reveals the three-dimensional association of a cloth’s structural constructing blocks on the nanoscale. Its first software targeted on a polycrystalline catalyst, enabling scientists to visualise crystal grains, grain boundaries, and defects—crucial options that affect catalyst efficiency. Past catalysis, XL-DOT gives unprecedented insights into the construction of varied purposeful supplies utilized in data know-how, power storage, and biomedical purposes.

Developments in Non-Damaging Imaging of Materials Microstructures

Zooming into the micro- or nanostructure of purposeful supplies — whether or not pure or man-made — reveals numerous coherent domains or grains. These grains are distinct areas the place molecules and atoms are organized in orderly, repeating patterns.

The association of those grains is intently tied to the fabric’s properties. Their measurement, orientation, and distribution can imply the distinction between a sturdy brick and a crumbling stone. They decide how ductile a steel is, how effectively a semiconductor transfers electrons, and the way effectively ceramics conduct warmth. This structural group additionally performs a crucial function in organic supplies; for instance, collagen fibers are product of interwoven fibrils, and their alignment impacts the mechanical power of connective tissues.

These domains are sometimes tiny: tens of nanometers in measurement. And it’s their association in three dimensions over prolonged volumes that’s property-determining. But till now, strategies to probe the group of supplies on the nanoscale have largely been confined to 2 dimensions or are damaging in nature.

Now, utilizing X-rays generated by the Swiss Mild Supply SLS, a collaborative staff of researchers from Paul Scherrer Institute PSI, ETH Zurich, the College of Oxford and the Max Plank Institute for Chemical Physics of Solids have succeeded in creating an imaging method to entry this data in three-dimensions.

“We Not Solely Look Inside, however With Nanoscale Decision”

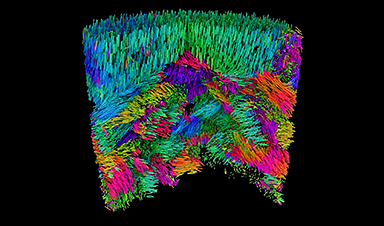

Their method is called X-ray linear dichroic orientation tomography, or XL-DOT for brief. XL-DOT makes use of polarized X-rays from the Swiss Mild Supply SLS, to probe how supplies take in X-rays otherwise relying on the orientation of structural domains inside. By altering the polarization of the X-rays, whereas rotating the pattern to seize photographs from completely different angles, the method creates a three-dimensional map revealing the inner group of the fabric.

The staff utilized their methodology to a bit of vanadium pentoxide catalyst about one micron in diameter, used within the manufacturing of sulfuric acid. Right here, they might determine minute particulars within the catalyst`s construction together with crystalline grains, boundaries the place grains meet, and modifications within the crystal orientation. In addition they recognized topological defects within the catalyst. Such options immediately have an effect on the exercise and stability of catalysts, so information of this construction is essential in optimizing efficiency.

Importantly, the tactic achieves excessive spatial decision. As a result of X-rays have a brief wavelength, the tactic can resolve constructions simply tens of nanometers in measurement, aligning with the sizes of options such because the crystalline grains.

“Linear dichroism has been used to measure anisotropies in supplies for a few years, however that is the primary time it has been prolonged to 3D. We not solely look inside, however with nanoscale decision,” says Valerio Scagnoli, Senior Scientist within the Mesoscopic Programs, a joint group between PSI and ETH Zurich. “Which means we now have entry to data that was not beforehand seen, and we will obtain this in small however consultant samples, a number of micrometers in measurement.”

Main the best way with coherent X-rays

Though the researchers first had the concept for XL-DOT in 2019, it could take one other 5 years to place it into apply. Along with complicated experimental necessities, a serious hurdle was extracting the three-dimensional map of crystal orientations from terabytes of uncooked information. This mathematical puzzle was overcome with the event of a devoted reconstruction algorithm by Andreas Apseros, first creator of the examine, throughout his doctoral research at PSI, funded by the Swiss Nationwide Science Basis (SNSF).

The researchers consider that their success in growing XL-DOT is partially because of the long-term dedication to growing experience with coherent X-rays at PSI, which led to unprecedented management and instrument stability on the coherent Small Angle X-ray Scattering (cSAXS) beamline: crucial for the fragile measurements.

That is an space that’s set to leap ahead after the SLS 2.0 improve: “Coherence is the place we’re actually set to realize with the improve,” says Apseros. “We’re very weak alerts, so with extra coherent photons, we’ll have extra sign and might both go to tougher supplies or greater spatial decision.”

A manner into the microstructure of numerous supplies

Given the non-destructive nature of XL-DOT, the researchers foresee operando investigations of techniques similar to batteries in addition to catalysts. “Catalyst our bodies and cathode particles in batteries are usually between ten and fifty micrometers in measurement, so it is a affordable subsequent step,” says Johannes Ihli, previously of cSAXS and presently on the College of Oxford, who led the examine.

But the brand new method isn’t just helpful for catalysts, the researchers emphasize. It’s helpful for every type of supplies that exhibit ordered microstructures, whether or not organic tissues or superior supplies for data know-how or power storage.

Certainly, for the analysis staff, the scientific motivation lies with probing the three-dimensional magnetic group of supplies. An instance is the orientation of magnetic moments inside antiferromagnetic supplies. Right here, the magnetic moments are aligned in alternating instructions when going from atom to atom. Such supplies preserve no internet magnetization when measured at a distance, but they do possess native order within the magnetic construction, a reality that’s interesting for technological purposes similar to sooner and extra environment friendly information processing. “Our methodology is among the solely methods to probe this orientation,” says Claire Donnelly, group chief Max Planck Institute for Chemical Physics of Solids in Dresden who, since finishing up her doctoral work within the Mesoscopic Programs group has maintained a powerful collaboration with the staff at PSI.

It was throughout this doctoral work that Donnelly along with the identical staff at PSI printed in Nature a way to hold out magnetic tomography utilizing circularly polarized X-rays (in distinction to XL-DOT, which makes use of linearly polarized X-rays). This has since been applied in synchrotrons all over the world.

With the groundwork for XL-DOT laid, the staff hope that it’ll, in an identical method to its circularly polarized sibling, turn into a extensively used method at synchrotrons. Given the a lot wider vary of samples that XL-DOT is related to and the significance of structural ordering to materials efficiency, the affect of this newest methodology could also be anticipated to be even higher. “Now that we’ve overcome lots of the challenges, different beamlines can implement the method. And we can assist them to do it,” provides Donnelly.

Reference: “X-ray Linear Dichroic Tomography of Crystallographic and Topological Defects” 11 December 2024, Nature.