- First-time customers can program their collaborative robots and industrial robots free of charge inside minutes

- System integrators and skilled customers can develop, share, and customise refined packages for application-specific options

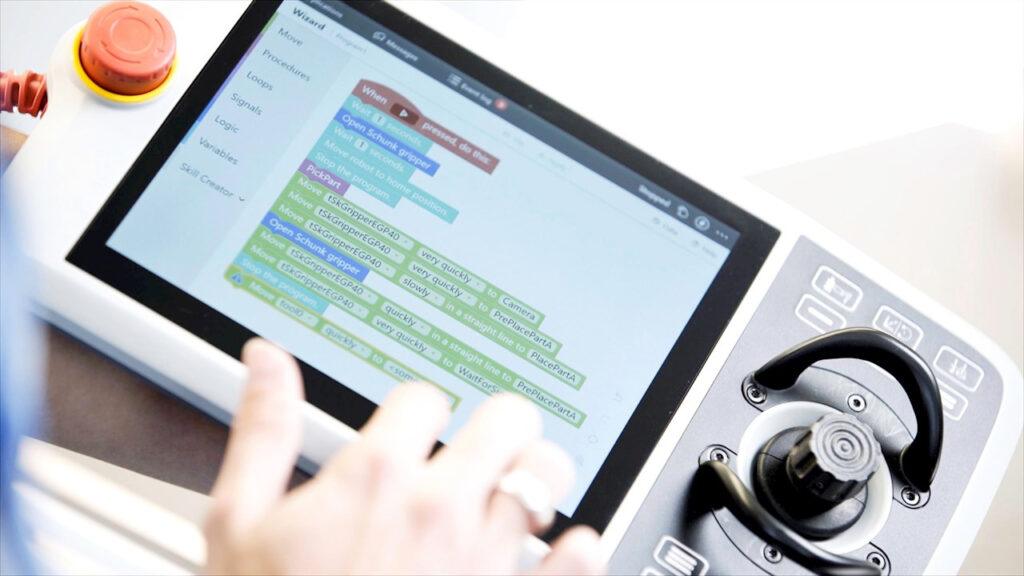

ABB Robotics has expanded the scope of its free Wizard Straightforward Programming software program for collaborative robots to incorporate all six-axis industrial robots working on an ABB OmniCore™ controller. This makes ABB the primary robotic producer to supply an easy-to-use no-code programming device for cobots and six-axis industrial robots. This lowers the obstacles to automation for early adopters and supplies ecosystem companions and integrators with an environment friendly device to assist their clients.

„If we wish to promote and advance using robotic automation on a world scale, we have to deal with the challenges and alternatives of the trade,“ says Marc Segura, head of the robotics division at ABB. „By including our six-axis industrial robots to Wizard Straightforward Programming, ABB Robotics is responding to the talents scarcity and rising demand from manufacturing firms for easy and easy-to-use programming software program for his or her robotic fleets.“

Create robotic purposes with out prior coaching

Wizard Straightforward Programming makes use of a graphic, drag-and-drop, no-code programming method designed to simplify the event of robotic purposes. The software program permits each first-time and skilled robotic customers to create purposes in minutes – a job that sometimes requires per week of coaching and one other week of improvement work. Since its launch in 2020, Wizard Straightforward Programming has been utilized in a variety of purposes along with ABB’s YuMi, SWIFTI™ and GoFa™ collaborative robots.

The software program presents customers the chance to create full packages for purposes reminiscent of arc welding or machine tending with out prior coaching. An intuitive graphical consumer interface means that you can customise present packages and pre-programmed blocks to manage numerous actions – from robotic actions to sign directions and drive management – for added flexibility.

Effectively generate particular codes for particular purposes

Wizard Straightforward Programming additionally consists of Ability Creator, a device that helps system integrators and consultants create customized, application-specific wizard blocks for his or her clients. Ability Creator simplifies the creation of recent blocks for extremely particular duties reminiscent of machine tending and welding, but in addition for troublesome purposes reminiscent of medical checks. Ecosystem companions who develop equipment reminiscent of grippers, feeding methods and cameras can have entry to a digital device that enables them to share product-specific functionalities no matter the kind of robotic for use.

Wizard Straightforward Programming is pre-installed on all cobots and new six-axis industrial robots working ABB’s OmniCore controller. The main robotic controllers of the OmniCore household are characterised by an vitality saving potential of 20 % on common and a excessive diploma of future-proofing – due to built-in digital connectivity and over 1,000 scalable capabilities.

Extra details about Wizard Straightforward Programming is offered right here.

Ähnliche Beiträge