The merchandise of the polyurethane (PU) trade comparable to foams, coatings and adhesives are quite a few and could be discovered in lots of areas of on a regular basis life. *

Polyols are a vital part within the manufacturing of polyurethane. These days they largely come from petroleum merchandise. *

In view of potential danger components such because the working out of fossil fuels, provide chain points, environmental issues and financial dangers you will need to develop alternate options as substitutes and dietary supplements to the prevailing petroleum derived polyols. *

Vegetable oils can be utilized to fabricate biobased polyols and varied oils comparable to linseed oil, rapeseed oil, canola oil, grapeseed oil, corn oil, rice bran oil, palm oil, olive oil, castor oil and soybean oil have already been used to make polyols for various functions.*

Many of the polyols derived from vegetable oils which are already commercially out there are comprised of soybean and castor oil and are primarily used for inflexible PU foam purposes. *

Thus far biobased supplies for versatile polyurethane foams (FPUFs) haven’t been studied as a lot as their inflexible counterpart. It is because, as a consequence of their chemical composition, there are limits to how a lot biobased supplies can be utilized within the versatile foam with out having an undesired impact on the froth’s mechanical properties. *

Coconut oil shouldn’t be typically used to fabricate versatile foam as a result of the coconut oil’s excessive stage of saturation makes it much less appropriate with many frequent strategies of making polyols, because the broadly used polyol-forming processes largely depend on the unsaturation of vegetable oil for functionalization.

To make coconut monoglycerides (CMG) or different plant-based oils usable for polyol-forming processes they should fulfil the identical structural necessities because the fossil-based merchandise. *

Within the article “Versatile Polyurethane Foams Modified with Novel Coconut Monoglycerides-Primarily based Polyester Polyols “ Christine Pleasure M. Omisol, Blessy Pleasure M. Aguinid, Gerson Y. Abilay, Dan Michael Asequia, Tomas Ralph Tomon, Karyl Xyrra Sabulbero, Daisy Jane Erjeno, Carlo Kurt Osorio, Shashwa Usop, Roberto Malaluan, Gerard Dumancas, Eleazer P. Resurreccion, Alona Lubguban, Glenn Apostol, Henry Siy, Arnold C. Alguno, and Arnold Lubguban describe how they investigated the potential of coconut monoglycerides (CMG) as a polyol uncooked materials particularly for versatile polyurethane foam (FPUF) purposes.*

The authors synthesized high-molecular-weight polyester polyols from coconut monoglycerides (CMG), a coproduct of fatty acid manufacturing from coconut oil, through polycondensation at completely different mass ratios of CMG with 1:5 glycerol:phthalic anhydride.*

The ensuing CMG-based polyols have been proven to work effectively in making versatile foam. *

Fourier rework infrared (FTIR) spectroscopy and atomic drive microscopy (AFM) have been used for the froth characterization. *

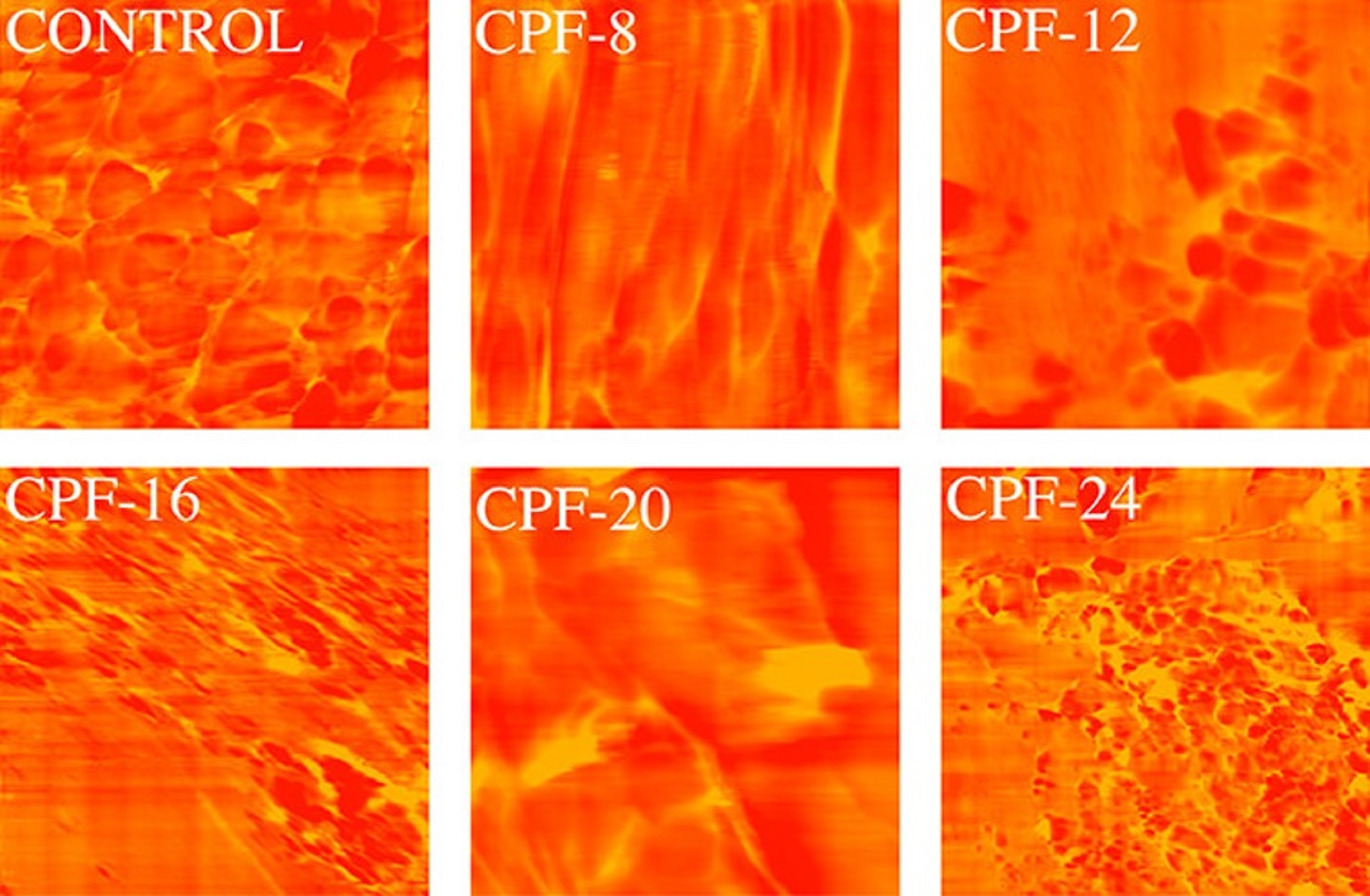

The modification of the froth formulation elevated the monodentate and bidentate urea teams, proven utilizing Fourier rework infrared (FTIR) spectroscopy, that promoted microphase separation within the foam matrix, confirmed utilizing atomic drive microscopy (AFM) and differential scanning calorimetry (DSC). *

Atomic drive microscopy (AFM) was used to judge the exhausting–mushy domains section separation of the froth. *

The atomic drive microscope was operated at a scan fee of 1.0 Hz in non-contact mode utilizing NanoWorld Pointprobe® NCHR Silicon AFM probes for normal tapping mode purposes. (typical resonance frequency 320 kHz, typical drive fixed 42 N/m). *

It could possibly be proven that density of the CMGPOL-modified polyurethane foams (CPFs) decreased, whereas a major enchancment of their tensile and compressive properties was noticed. *

The investigations by Christine Pleasure M. Omisol et al. resulted in a brand new sustainable polyol uncooked materials that can be utilized to switch petroleum-based foam and produce versatile foams with various properties that may be tailor-made to satisfy particular necessities. *

Atomic drive microscopy (AFM) section photos of CMGPOL-modified polyurethane foams (CPF) and management foam measured with a measurement scan of three μm × 3 μm displaying mushy and exhausting areas represented by pink and yellow colours, respectively.

*Christine Pleasure M. Omisol, Blessy Pleasure M. Aguinid, Gerson Y. Abilay, Dan Michael Asequia, Tomas Ralph Tomon, Karyl Xyrra Sabulbero, Daisy Jane Erjeno, Carlo Kurt Osorio, Shashwa Usop, Roberto Malaluan, Gerard Dumancas, Eleazer P. Resurreccion, Alona Lubguban, Glenn Apostol, Henry Siy, Arnold C. Alguno, and Arnold Lubguban

Versatile Polyurethane Foams Modified with Novel Coconut Monoglycerides-Primarily based Polyester Polyols

ACS Omega 2024, 9, 4, 4497–4512

DOI: https://doi.org/10.1021/acsomega.3c07312

The article “Versatile Polyurethane Foams Modified with Novel Coconut Monoglycerides-Primarily based Polyester Polyols” by Christine Pleasure M. Omisol, Blessy Pleasure M. Aguinid, Gerson Y. Abilay, Dan Michael Asequia, Tomas Ralph Tomon, Karyl Xyrra Sabulbero, Daisy Jane Erjeno, Carlo Kurt Osorio, Shashwa Usop, Roberto Malaluan, Gerard Dumancas, Eleazer P. Resurreccion, Alona Lubguban, Glenn Apostol, Henry Siy, Arnold C. Alguno and Arnold Lubguban is licensed beneath a Artistic Commons Attribution 4.0 Worldwide License, which allows use, sharing, adaptation, distribution and copy in any medium or format, so long as you give acceptable credit score to the unique creator(s) and the supply, present a hyperlink to the Artistic Commons license, and point out if modifications have been made. The photographs or different third-party materials on this article are included within the article’s Artistic Commons license, except indicated in any other case in a credit score line to the fabric. If materials shouldn’t be included within the article’s Artistic Commons license and your supposed use shouldn’t be permitted by statutory regulation or exceeds the permitted use, you’ll need to acquire permission straight from the copyright holder. To view a replica of this license, go to https://creativecommons.org/licenses/by/4.0/.